CVT Innovation To Transform CVT Market

Over the past years there has been a significant increase in the production volumes of CVT's by Japanese manufacturer JATCO, reporting growth of 50% in its cumulative production over a two-and-a-half-year period.

Such a remarkable increase in global CVT production means that CVT will play a significant role in the future of small passenger vehicle production.

According to Bosch Transmissions (the largest manufacturer of the metal push belt CVT) global market share of CVT is currently in the region of 20% and this is expected to grow exponentially in the small passenger vehicle sector. Director of global propulsion systems at General Motors, Larry Nitz, stated that CVT has a place in small cars; adding that his company will continue looking at CVT technology going forward even though GM’s overall transmission production still includes 40% manual transmissions.

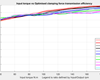

It is known however that the mechanical efficiency of current commercial CVT'’s are lacking when compared to manual transmissions. This is as a result of power loss in current commercial CVT’s that is consumed by a hydraulic control system and the losses created in the two (in series) dynamic friction drive interfaces.

CVT’s compensate for the losses by continually operating the engine at its maximum efficiency, given a certain load and speed and also facilitates the incorporation of hybrid components. Due to its infinite number of ratios, CVT’s can be programmed to provide all driver preferences, for example, stepless smooth shifting or artificially programmed stepped ratios. The advantages of the CVT over manual transmissions, however, come at a higher cost to the end user, while also being heavier with increased complexity.

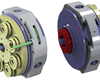

To overcome these barriers, Varibox developed a product, the RADIALcvt, which provides an alternative CVT design that includes a number of very significant advantages. The RADIALcvt does not have a hydraulic control system, only contains one dynamic friction drive in series and is configured to have a constant input friction drive radius. This Varibox product does not only enable low cost manufacturing but will also reduce emissions for environmental sustainability.

The RADIALcvt is configured to have a constant input friction drive radius and the clamping force is therefore constant and generated via mechanical springs. In addition, it also splits input power into six parallel power paths via a patented configuration to increase power density and eliminates the use of exotic steels normally associated with toroidal CVT’s.

The RADIALcvt has been in development since 2015 and was created to specifically use the well-known and existing traction fluid technology which allows for very efficient metal on metal friction drive through a traction fluid film. This technology has been in existence since the 80’s and is the functioning principle for all current commercial CVT’s as well as developmental toroidal CVT’s.

Reliance on this technology drastically reduces the development complexity, cost and time to serial production of the RADIALcvt.

Varibox CVT Technologies (Pty) Ltd, also announced a geared motor application design for their flagship CVT invention, called ROTORcvt, today. The ROTORcvt includes a geared neutral ratio which eliminates the use of a clutch or torque converter and provides excellent low speed maneuverability. The ROTORcvt is ideal for small vehicles and geared motor industrial applications.

The most attractive market for both RADIALcvt and ROTORcvt is the small passenger vehicle market because both innovations provide a cost effective, high mechanical efficiency solution when compared to other transmission solutions in this market.

The RADIALcvt and ROTORcvt solutions are thus in line with JATCO, Bosch Transmissions and GM’s forecasts that the small passenger vehicle transmission market will see a CVT transmission growth. Consequently, the RADIALcvt and ROTORcvt will facilitate this trend by providing solutions with a cost closer to that of the manual transmission that is currently widely used in this sector.