RADIALcvt Testing

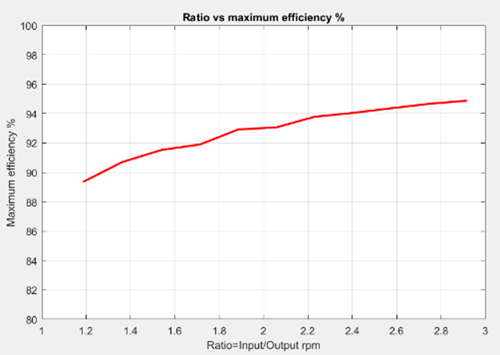

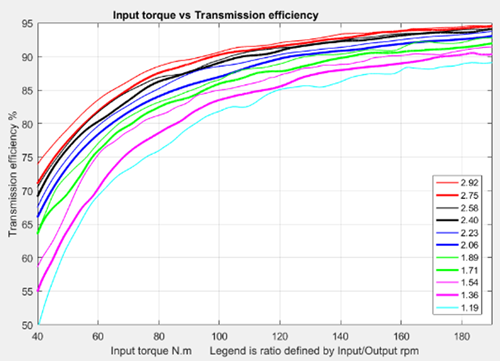

Varibox’s RADIALcvt has come a long way over the last two years. After the introduction of the enhanced Gen II (To find out more, follow this link ), we went about seeking and selecting a suitable partners to build, test and commercialise what we believe to be a world beater in terms of efficiency in the CVT market. A prototype was built and a first series of tests where conducted by the independent University of the Witswatersrand. These tests were completed in November 2019. And Varibox is proud to announce that peak efficiency increased from 90% in the first prototype to an unprecedented 94.7% in the second generation (Gen II) prototype. The graph below depicts this peak efficiency, whilst the second graph depicts the efficiency map through the various ratios and loads.

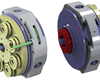

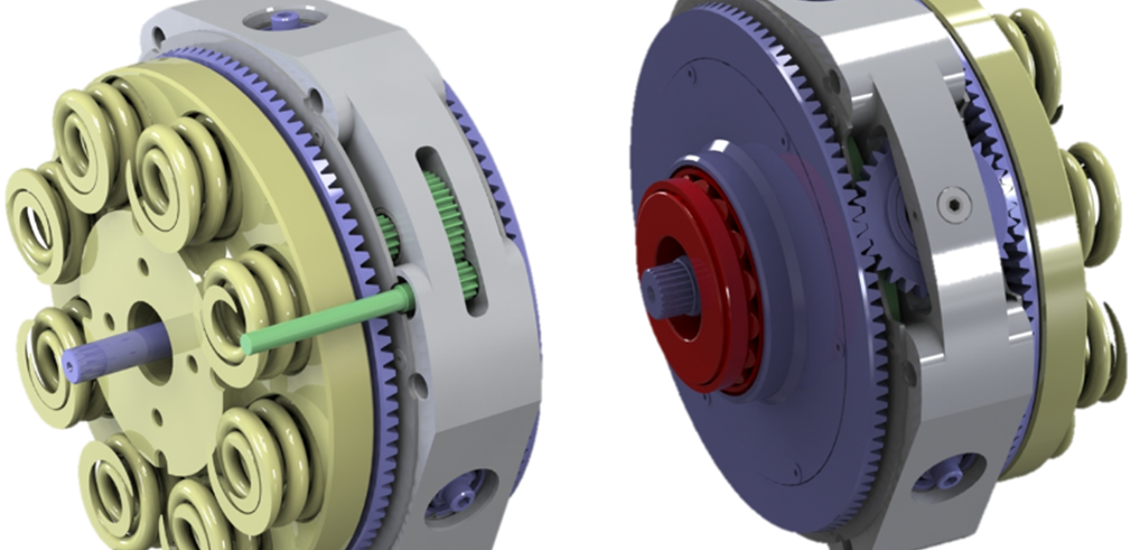

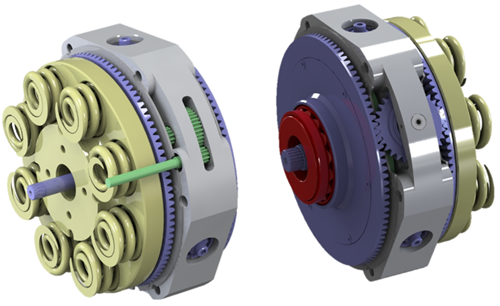

The images below shows the heart of the actual RADIALcvt Gen II prototype that was tested.

The RADIALcvt Gen II offers a very compact, robust and efficient continuously variable transmission. The current prototype is rated at 300N.m input torque in all ratios with a ratio range of 3:1 to 1.15 : 1. The testing facility at the University of the Witwatersrand limited testing to 200N.m input torque however. The mass of the current prototype is 65kg. This RADIALcvt Gen II prototype makes use of a constant clamping force. However current designs and models include a loading cam which will allow for variable clamping; This was added as it will increase mechanical efficiency at partial loads very significantly.

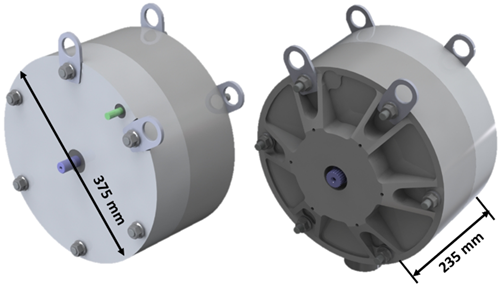

The images below depict this and also give the reader an idea of the dimensions and compactness of the current prototype.

A video of the RADIALcvt rationale and functioning can be viewed at this link

The RADIALcvt Gen II prototype was manufactured by local technology licensee Conax Machine Solutions and is in the process of being commercialised in the geared motor and electric vehicle market for mining applications.

The photo below shows the actual testing under way